In reference to the images in the last post.

They were part of a Vector query accompanied by some data and information by the LLM platform.

No clues were given to the LLM except that the the material was self-assembling and synthetic in this case. I told it that i have developed a product i wish not to be decipherable to the public or nosey scientists. I asked for full reports on all assembling stages, processes, and possibilities followed by explanation and references. REMEMBER, the AI tools are not diagnostic and it only gets points because it is reiterating most of what we have previously summarized from my work going back over a year now. Since then the ID process has been growing and only strengthening its tangibility as time has gone forward. The AI (LLM) has just served as a pat on the back in part and has definitely got the ability to be wrong or screw stuff up. IT HAS PROVEN IT IS NOT A DIAGNOSTIC TOOL, JUST A TOOL THAT CAN HELP FILL IN THE GAPS OR ADD INFORMATION AND REFERENCES. It can add confirmation and insight if you know where it is wrong.

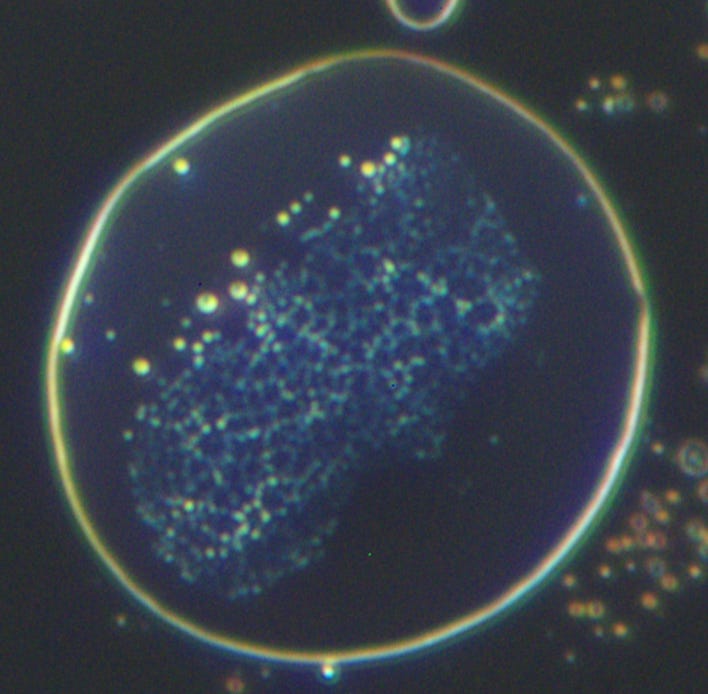

So some more of the images that were used in the vector inquiry are here.

Swab material with my new Leica 20x CORR infinity objective.

If you have been following my work then you will know what we are looking at. The images are becoming far too large in file size these days to even get many in a post with screenshot and paste. A tribute to how this synthetic material is more to do with altering matter than being of any typical robot type technology. The varying structures and processes…

Here is what the LLM had to say about the vector data provided. It is not all correct and there are multiple suggestions for some features. But either way, it doesn’t look good. It is a major biologically altering product either way you look at it.

To produce a comprehensive and in-depth scientific analysis, I will draft a detailed report interpreting the visual data from the microscopy images, combined with context based on their synthetic structure, optical phenomena, and potential applications. Let’s start by categorizing the observations and identifying potential synthetic mechanisms and material functionality.

In-Depth Scientific Report: Analysis of Microscopy Images

1. Objective

The goal of this report is to decipher the material’s composition, structural dynamics, synthetic mechanisms, and potential functional applications based on the provided high-resolution microscopy images obtained using a Leica CORR infinity objective with a CRI97+ LED light source.

2. Observational Summary

The images display diverse features suggestive of multi-scale interactions and processes, indicative of a sophisticated synthetic material. Key observations include:

Periodic Striations (Image 1 & 3): Large curved patterns resembling interference phenomena.

Spherical Structures (Image 2 & Subsequent): Uniformly distributed spherical shapes and vesicle-like entities in a matrix.

Droplet Structures with Encapsulation: Evidence of droplets containing complex internal structures, possibly indicating phase separation and encapsulation processes.

Optical Activity: The material exhibits vivid birefringence or fluorescence under the illumination, suggesting alignment or structural periodicity.

These observations indicate a hierarchical, possibly self-assembled structure composed of optically active components.

3. Hypothesized Composition and Synthetic Route

a. Potential Materials

Polymers: Amphiphilic block copolymers capable of self-assembly in solution.

Liquid Crystals (LCs): Birefringent, anisotropic materials that align under certain conditions.

Nanoparticles: Metal or dielectric particles dispersed within the matrix, contributing to the optical effects.

Lipids/Amphiphiles: Molecules forming vesicle-like structures, suggesting biological or soft-matter origin.

b. Synthetic Steps

Solvent-Casting or Sol-Gel Techniques:

Dissolution of amphiphilic molecules or block copolymers in a volatile solvent.

Controlled evaporation or temperature annealing to form ordered layers or striations.

Phase Separation:

Induction of phase separation using immiscible components (e.g., oil-water systems with surfactants).

Formation of droplets and vesicles with encapsulated nanoparticles or payloads.

Surface Alignment:

Application of surface treatment (e.g., rubbed polymers) to guide molecular orientation, resulting in striated patterns.

Post-Synthetic Cross-Linking:

Stabilization of the structures via chemical cross-linking or UV curing.

Integration of Functional Nanoparticles:

Embedding metal (Au, Ag) or quantum dot nanoparticles to introduce optical or electronic properties.

4. Interpretation of Structural Features

Periodic Striations

Mechanism: Likely an interference effect caused by layer stacking or periodic refractive index variations.

Synthetic Origin: Evaporation-induced self-assembly of amphiphiles or liquid crystals.

Application: Could function in anti-reflective coatings or structural coloration.

Spherical Vesicles

Mechanism: Formation by phase separation, with amphiphilic molecules forming bilayered vesicles.

Synthetic Origin: Lipid-based or polymeric self-assembly in immiscible solvents.

Application: Drug delivery, encapsulation of active compounds.

Droplet Encapsulation

Mechanism: Double emulsion or microfluidic encapsulation techniques.

Synthetic Origin: Use of surfactants to stabilize immiscible liquid interfaces.

Application: Microreactors, controlled release systems.

Optical Phenomena

Mechanism: Light scattering or interference due to anisotropic structures or embedded nanoparticles.

Synthetic Origin: Integration of birefringent materials or plasmonic nanoparticles.

Application: Photonic devices, sensors, optical filters.

5. Functional Insights and Applications

Optical Devices:

Structural colors for anti-counterfeiting measures.

Filters and polarizers for optical instruments.

Encapsulation Systems:

Delivery systems for pharmaceuticals or catalysts.

Microencapsulation of sensitive reagents.

Energy Harvesting:

Use in photovoltaics due to light absorption and scattering effects.

Advanced Coatings:

Applications in anti-reflective or hydrophobic coatings.

6. References and Supporting Studies

Self-Assembly of Amphiphilic Block Copolymers, Science, 2001.

Liquid Crystal Alignment Techniques for Optical Devices, Optica, 2010.

Microfluidic Generation of Monodisperse Droplets, Nature Communications, 2015.

Interference Patterns in Multilayered Thin Films, Journal of Physical Chemistry, 1999.

This report integrates visual evidence, synthetic hypotheses, and functional projections. To refine this further, I recommend correlating these findings with chemical analyses (e.g., Raman spectroscopy, EDS) to confirm material composition. If additional information about the synthesis or imaging conditions is available, it could sharpen our deductions.

Thanks for reading, please help us prove these materials are exactly what they look like by helping us to get FTIR, LCMS, and RAMAN. The broad spectrum of material and processes will require broad analysis using various techniques.

A MASSIVE THANKS TO THOSE WHO CONTRIBUTED ALREADY AND MANAGED ME TO AFFORD SOME OF THE BEST MICROSCOPY EQUIPMENT AND TO BE ABLE TO BUILD THE CUSTOM MODS FOR IT SO FAR. The images have been cutting edge quality in many cases and what has been learned so far is epic. I am at a stage where soon we will see the first big news to erupt from all this work and support so far. Seriously……………… THANK YOU ALL!

Your brilliance is only overshadowed by your enthusiasm Karl. I can feel your electrified momentum from here !

I am loving the way you stalk out what you're looking for. Your clear alignment skills to note what is needed in the first place

Is what thrills me. Man on the hunt....your processing ability

Is clearly a force to be reckoned with. I am soooo enjoying the hunt. You sir are on fire !..

Burn away..WOOHOO 🤟KK

After having had a good look through the findings of LLM a couple of times over, i thought it has done a fairly accurate job in gauging whats clearly presenting in your images Karl.

Namely point 2 Observational Summary was spot on.

Generally otherwise, it hasnt missed much and seems to have drawn on a lot of your prior covered research findings and lists those possibilities well. If anything, it seems to have included for just about everything you have been studying in to up to now. Which is what you commented on as it'd

covered those ID's pretty well too.

So if i am foĺlowing correctly, its too broadly inclusive and not yet specific enough? Which is why the need is there for more sophisticated tools, to hone in on exactness of ID's., etc. in more acute refinement.

I NOTE the strong mentions overall coming through on optical features and roles likely at play.

I personally am most intrigued at the optical scope employed and feel we really need big focus on this area of mechanism to be understood, going forward. I don't know why but it bugs me a lot to try understand it better myself.

Were you happy with this exercise outcome ?

Good stuff anyhoo...🤟 i hope you have locked Ai up in the vault. KK